History of HDG

The recorded history of galvanizing goes back to 1742 when a French chemist named P.J. Malouin, in a presentation to the French Royal Academy, described a method of coating iron by dipping it in molten zinc. In 1836, Stanilaus Tranquille Modeste Sorel, another French chemist, obtained a patent for a means of coating iron with zinc, after first cleaning it with 9% sulfuric acid and fluxing it with ammonium chloride. A British patent for a similar process was granted in 1837. By 1850, the British galvanizing industry was using

10,000 tons of zinc a year for the protection of steel. Galvanizing is found in almost every major application and industry where iron or mild steel is used. The utilities, chemical process, pulp and paper, automotive, and transportation industries, to name just a few, historically have made extensive use of galvanizing for corrosion control. They continue to do so today. For over 150 years, hot-dip galvanizing has had a proven history of commercial success as a method of corrosion protection in myriad applications worldwide.

The recorded history of galvanizing goes back to 1742 when a French chemist named P.J. Malouin, in a presentation to the French Royal Academy, described a method of coating iron by dipping it in molten zinc. In 1836, Stanilaus Tranquille Modeste Sorel, another French chemist, obtained a patent for a means of coating iron with zinc, after first cleaning it with 9% sulfuric acid and fluxing it with ammonium chloride. A British patent for a similar process was granted in 1837. By 1850, the British galvanizing industry was using

10,000 tons of zinc a year for the protection of steel. Galvanizing is found in almost every major application and industry where iron or mild steel is used. The utilities, chemical process, pulp and paper, automotive, and transportation industries, to name just a few, historically have made extensive use of galvanizing for corrosion control. They continue to do so today. For over 150 years, hot-dip galvanizing has had a proven history of commercial success as a method of corrosion protection in myriad applications worldwide.

What is corrosion?

Corrosion

is the reaction between a material and its environment that produces a

deterioration of the material and alters its mechanical properties. The

actual corrosion process that takes place on a piece of bare mild steel

is very complex due to factors such as variations in the

composition/structure of the steel, presence of impurities due to the

higher instance of recycled steel, uneven internal stress, or exposure

to a non-uniform environment.

It

is very easy for microscopic areas of the exposed metal to become

relatively anodic or cathodic. A large number of such areas can develop

in a small section of the exposed metal. Further, it is highly possible

that several different types of galvanic corrosion cells are present in

the same small area of the actively corroding piece of steel. As the

corrosion process progresses, the electrolyte may change due to

materials dissolving

It

is very easy for microscopic areas of the exposed metal to become

relatively anodic or cathodic. A large number of such areas can develop

in a small section of the exposed metal. Further, it is highly possible

that several different types of galvanic corrosion cells are present in

the same small area of the actively corroding piece of steel. As the

corrosion process progresses, the electrolyte may change due to

materials dissolving

in

or precipitating from the solution. Additionally, corrosion products

might tend to build up on certain areas of the metal. These corrosion

products do not occupy the same position in the given galvanic series as

the metallic component of their constituent element. As time goes by,

there may be a change in the location of relatively cathodic or anodic

areas and previously uncorroded areas of the metal are attacked and

corrode. This eventually will result in uniform corrosion of the area.

The rate at which metals corrode is controlled by factors such as

electrical potential and resistance between anodic and cathodic areas,

pH of the electrolyte, temperature and humidity.

How do you protect iron and steel from corrosion?

Barrier

protection is perhaps the oldest and most widely used method of

corrosion protection. It acts by isolating the metal from the

electrolytes in the environment. Two important properties of barrier

protection are adhesion to the base metal and abrasion resistance.

Cathodic

protection is an equally important method for preventing corrosion.

Cathodic protection requires changing an element of the corrosion

circuit, introducing a new corrosion element, and ensuring that the base

metal becomes the cathodic element of the circuit. Hotdip galvanizing

provides excellent barrier and cathodic protection. The sacrificial

anode method, in which a metal or alloy that is anodic to the metal to

be protected is placed in the circuit and becomes the anode. The

protected metal becomes the cathode and does not corrode. The anode

corrodes, thereby providing the desired sacrificial protection. In

nearly all electrolytes encountered in everyday use, zinc is anodic to

iron and steel. Thus, the galvanized coating provides cathodic corrosion

protection as well as barrier protection.

Service-Life Chart for Hot-Dip Galvanized Coatings

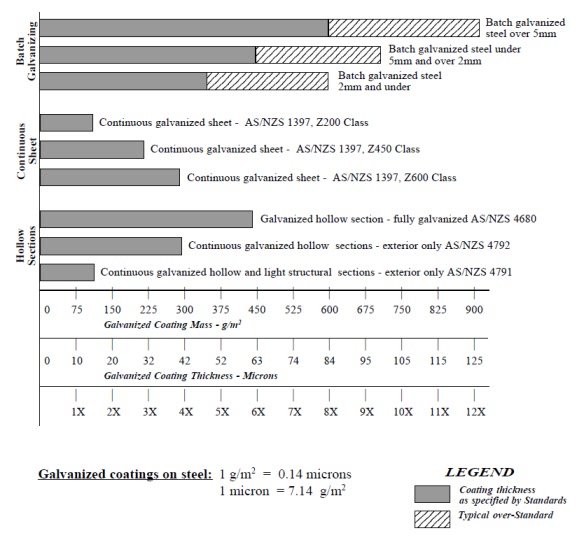

Continous and Batch Galvanize

There

are many types of coatings that are specified as hot dip galvanized.

The process involves immersing steel in molten zinc. The zinc reacts

with the steel to form the galvanized coatings. The time the steel is

immersed in the zinc along with post-galvanizing treatment controls the

coating thickness, appearance and other characteristics

Hot

dip galvanized coatings are applied to steel to improve the

anti-corrosion performance of the steel to ensure that it lasts as long

as possible with a minimum of maintenance. Standards currently being

developed for the housing industry have set a benchmark of at least 50

years as the acceptable life of structural building products. Only hot

dip galvanized steel products with the heaviest galvanized coatings are

capable of meeting this requirement.

The

Australian Standard AS 4680 - 1999 , Hot Dipped Galvanized Coatings on

Ferrous Articles, includes galvanized coating standards on sheet, wire,

tube and general articles. A great deal of confusion exists through the

inclusion of galvanized coatings with significantly different coating

characteristics within the same Australian Standard.

COATING THICKNESS COUNTS

All

sheet, wire and many tube products are CONTINUOUSLY galvanized. This

means that the coating is applied at high speed and the coating

thickness is controlled by the process. Immersion time in the zinc is

measured in seconds. Alternatively, in the BATCH hot dip galvanizing

process steel items are immersed for periods ranging from 3-10 minutes,

depending on the mass of the items being galvanized.

These completely different methods of applying galvanized coatings produce different types of coatings.

There

are 4 main differences that impact on anti-corrosion performance of

BATCH galvanized steel compared to CONTINUOUSLY galvanized steel. These

are:

1.

Coating thickness - BATCH galvanized items of the same section

thickness are typically at least 3 TIMES thicker than similar

CONTINUOUSLY galvanized coatings on sheet and tube.

2.

Coating hardness - BATCH galvanized items have much thicker zinc/iron

alloy layers in the coatings which gives BATCH galvanized items 5 TIMES

the abrasion resistance of CONTINUOUSLY galvanized coatings.

3.

Coating integrity - BATCH galvanized coatings apply a uniform heavy

coating to all internal and external surfaces, edges and cavities.

CONTINUOUSLY galvanized coating will always have exposed bare steel at

cut edges. CONTINUOUSLY galvanized hollow sections are fully galvanized

on the external surfaces only.

4.

Coating mass - The cathodic protection of exposed steel by zinc depends

of the mass of the zinc in relation to the area of exposed steel.

Because of the drainage characteristics of BATCH galvanized coatings,

the coating mass on BATCH galvanized products is significantly higher

(typically 3-5 times) in proportion to thickness than CONTINUOUSLY

galvanized coatings. Hot rolled medium structural sections commonly

achieve coating mass levels exceeding 1000 g/m2.

MORE COATING THICKNESS = LONGER COATING LIFE

150

years of field testing has determined that all things being equal,

galvanized coating life is equivalent to galvanized coating thickness.

When comparing BATCH galvanized coatings to CONTINUOUSLY galvanized

coating, all things are not equal.

THE CUT EDGE FACTOR

All

CONTINUOUSLY galvanized sections have exposed steel at cut edges and

rely on the adjacent zinc in the coating to provide cathodic protection

to the bare steel. This requirement accelerates the rate of corrosion of

the galvanized coating at cut edges. The thicker the CONTINUOUSLY

galvanized section, the faster the rate of coating corrosion at cut

edges because of the greater area of bare steel exposed. Even if it was

possible to apply a CONTINUOUSLY galvanized coating to a steel item to

the same thickness as a BATCH galvanized item, the cut edge factor gives

the BATCH galvanized coating a life typically 1.5 TIMES greater.

COMPARISON OF GALVANIZED COATINGS

CONTINUOUSLY galvanized coatings comply very closely to their specified coating mass. BATCH

galvanized coatings on hot rolled steel sections almost always exceed their minimum specified coating

mass.

Thanks for sharing this post!

BalasHapusThat was incredibly helpful

Elcometer